- #Asme y14.5 orthographic projections manual

- #Asme y14.5 orthographic projections full

- #Asme y14.5 orthographic projections software

Specifi cation of the acceptable variation is done through the application of tolerances. Because of these factors, it is essential that the amount of acceptable variation be defi ned so that processes can be correctly selected. Cutting tools, tool setup, cutting feed and speed, cutting lubricant and coolant, product material, product design, and even temperature can introduce feature variation. Many factors in addition to the machine quality affect fea- ture variation. Regardless of the precision that is possible today, all machine processes produce a fi nite amount of feature variation in every fabricated part. In the past few decades, however, machines have improved and can achieve amazing accuracies. Although a computer-generated model contains precise defi nition of what was created through the design process, production machines cannot produce perfect parts from the model.

#Asme y14.5 orthographic projections manual

Computer-generated product defi nition data can contain dimensional data with accuracies far beyond what could be achieved with manual drafting practices.

#Asme y14.5 orthographic projections software

Now, computer software and hardware have replaced drawing instruments in many companies. During the last two decades of the 20th century, CAD tools emerged. During the 20th century, drawing instruments advanced suffi ciently to enable production of very accurate manually cre- ated drawings. The methods for completing product defi nition data have advanced along with the capabilities of production and inspection machines. Properly specifi ed dimen- sional requirements allow for effi cient utilization of today’s industrial capabilities. It is the responsibil- ity of the person who applies tolerances to master the standardized practices. Utilization of a recognized standard is essential to clearly communicate dimensions and tolerances defi ning product requirements. However, by the 1990s, many countries had their own standards for dimensioning and tolerancing. The United States was a leader in this area of standards development and greatly infl uenced standards throughout the world. Over time, common dimensioning and tol- erancing practices began to develop and result in standards. requirement such as perpendicularity could be as numerous as the number of people writing such a specifi cation.

#Asme y14.5 orthographic projections full

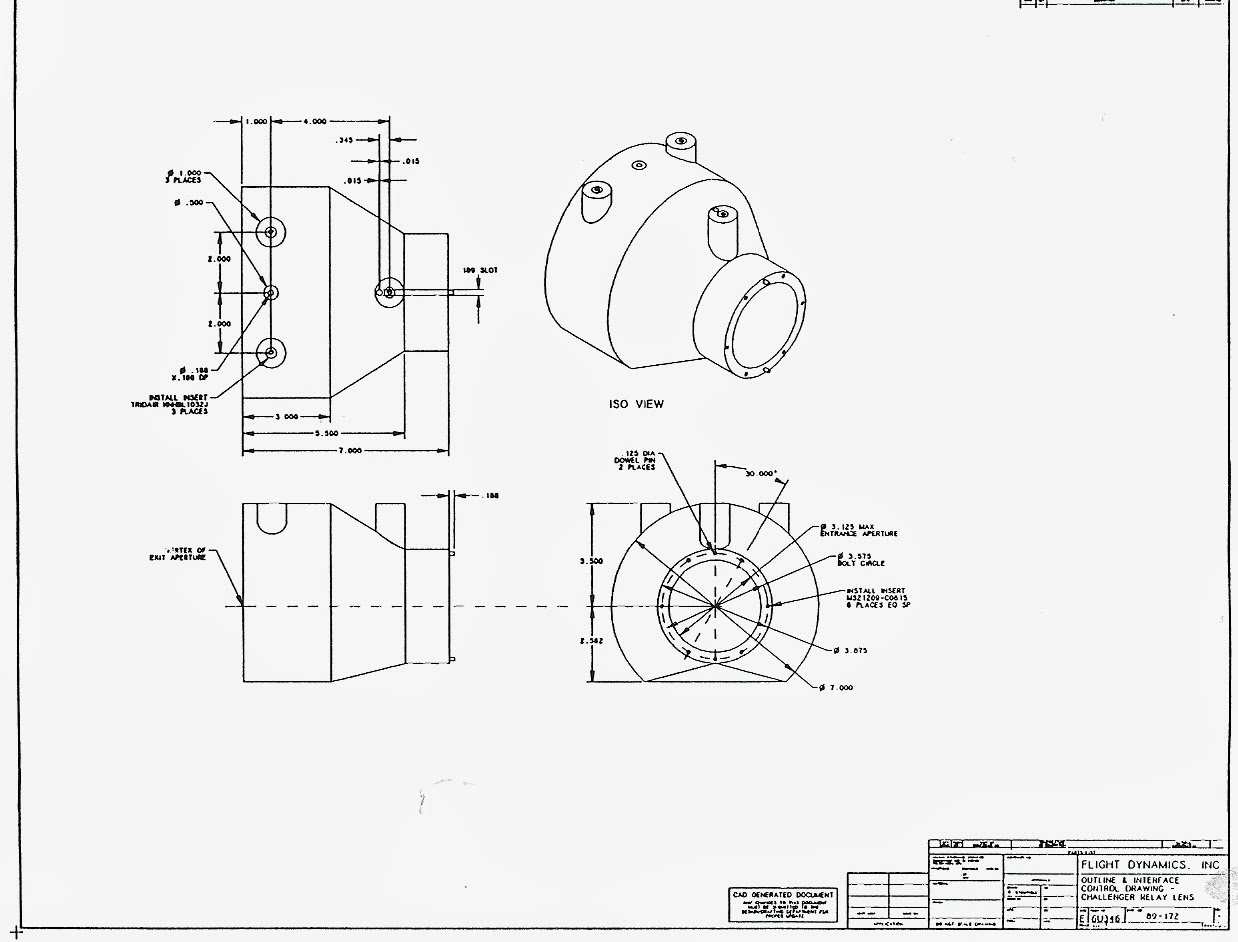

Y14 Standards Discover our full collection of Y14 standards that guide you across product development.5 Chapter 1 Introduction to Dimensioning and Tolerancing Copyright Goodheart-Willcox Co., Inc. Additionally, the subject matter has been restructured for better readability, with profile, orientation, and form now in separate sections, and material within sections reorganized.ĪSME Y14.5-2018 is a replacement of ASME Y14.5-2009. Important changes include: concept of feature of size datum references and degrees of freedom composite position tolerances surface boundaries and axis methods of interpretation profile tolerances and symbology and modifiers tools. This revision also emphasizes the use of profile for location tolerances applied to surfaces. Orthographic views for product definition, model views were added in many figures throughout the Standard.

Because of the widespread use of computer-aided design (CAD) and the industry transition toward reduced use of

Now, a consensus committee of experts has revised Y14.5 for 21st-century applications. By providing uniformity in drawing specifications and interpretation, GD&T reduces guesswork throughout the manufacturing process - improving quality, lowering costs, and shortening deliveries. GD&T is an essential tool for communicating design intent - that parts from technical drawings have the desired form, fit, function and interchangeability. The Y14.5 standard is considered the authoritative guideline for the design language of geometric dimensioning and tolerancing (GD&T.) It establishes symbols, rules, definitions, requirements, defaults, and recommended practices for stating and interpreting GD&T and related requirements for use on engineering drawings, models defined in digital data files, and in related documents.

0 kommentar(er)

0 kommentar(er)